The ship would not go anywhere without the work that is done below decks. We took the tour and saw the master control panel, the engines, the AC units, the water desalinization plant, the hydraulic system used to deploy the stabilizers. There were two workers in bunny suits and masks working on the exhaust system or the air intake system that we almost missed since they blended in so well. We went through our tour which lasted about an hour. Oddly, most of us felt a bit off at some point in the tour. Later we found out that a squall with 55 knot gusts had hit the boat. It must have spun the boat around giving our inner ears a real work out.

Behind the Crew Only Door

Controlling behavior

Our guide

The brains of the operation

Synchronizing

A warning sign came up while we were in the room

Escape oxygen

The exhaust that needs to be insulated

One worker of two

In an emergency think positive

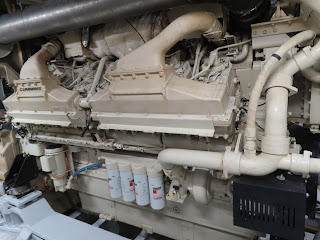

Engine #1

So many wires

So much water to shuttle around

Valve after valve

Brown water if part of the system

Engine 2 of 5

The oil filling station

The escape hatch to the top of the ship

Engine #3

Leslie was enthralled

The osmosis system

Here are the stabilizer units

Hydraulically driven

More water management

Are we on a canoe trip or what?

Precautions for the watertight door

Upon our return upstairs, we saw this mayhem

The bad weather continues